In modern concrete production, aggregates account for the largest proportion of raw materials and play a decisive role in final product quality. Whether for ready-mix concrete plants, road construction projects, or infrastructure development, stable and accurate aggregate proportioning is the foundation of consistent production.

An aggregate batching plant is designed to store, weigh, and proportion different sizes of aggregates according to preset ratios, ensuring a continuous and precise supply of materials to the mixing system. Rather than mixing materials, its core function is to control aggregate flow and accuracy before mixing, which direclty affects output quality, production efficiency, and material cost.

For contractors and plant owners, understanding how an aggregate batching plant works – and how it integrates with a complete batching plant solution – is essential when selecting equipment for long-term, stable production.

What Is an Aggregate Batching Plant

An aggregate batching plant is a material proportioning system used to accurately weigh and batch various aggregates – such as sand, gravel, and crushed stone – before they are conveyed to a concrete mixing unit.

Unlike the mixer, which blends materials together, the aggregate batching plant forcuses on precise measurement and controlled feeding. It is typically integrated into a concrete batching plant, although in some configuration it can also operate as a standalone aggregate batching system.

Aggregate Batching Plant vs. Concrete Batching Plant

These two terms are often confused, but they serve different functions:

Aggregate batching plant – for storing, weighing, and proportioning aggregates

Concrete batching plant – a complete system that includes aggregate batching, cement weighing, water and admixture systems, and mixer

In simple terms, the aggregate batching plant is a critical subsystem within the full batching plant.

Aggregate Batching Plant vs. Aggregate Bins

Aggregate bins are only storage units for different aggregate sizes. An aggregate batching plant, however, includes:

- Storage bins

- Weighing and measuring devices

- Conveying systems

- Automated control systems

Main Components of an Aggregate Batching Plant

A complete aggregate batching plant is not a single piece of equipment, but a coordinated system composed of multiple functional units. Each component plays a critical role in ensuring accurate proportioning, stable feeding, and continuous production.

A well-designed aggregate batching system allows flexibility in configuration, making it suitable for different project scales, aggregate types, and production requirements.

Aggregate Storage Bins

Aggregate storage bins are used to store different sizes and types of aggregates separately, such as sand, gravel, and crushed stone. The number and capacity of bins directly affect production flexibility and output efficiency.

Typical configurations include:

- 2-bin, 3-bin, 4-bin, or multi-bin layouts

- Side-by-side or inline arragements

- Independent or integrated steel structures

The bin design must ensure smooth discharge, prevent material blockage, and support stable feeding during continuous operation.

Aggregate Weighing System

The aggregate weighing system is the core accuracy component of an aggregate batching plant. It measures each type of aggregate according to preset proportions before conveying them to the mixing unit.

Common weighing methods include:

- Weigh hopper systems

- Belt scale weighing systems

High-quality weighing systems ensure:

- Accurate aggregate proportioning

- Reduced material waste

- Consistent concrete or asphalt quality

Conveying System

Once weighed, aggregates are transferred to the mixing unit through a conveying system. Depending on plant design and site conditions, different conveying solutions can be applied.

Typical conveying options include:

- Belt conveyors for continuous and high-capacity transport

- Skip hoppers for compact or vertical plant layouts

The conveying system must operate smoothly to maintain proudction rhythm and avoid material segregation.

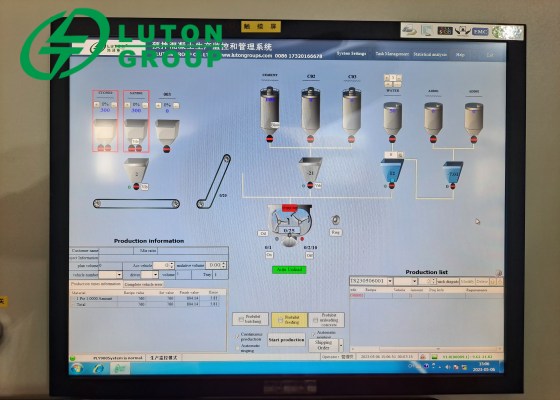

Control System

The control system serves as the central management unit of the aggregate batching plant. Through PLC-based automation, it coordinates aggregate feeding, weighing, and discharge according to the production recipe.

Key functions include:

- Automatic batching and proportion control

- Real-time monitoring of weighing accuracy

- Recipe storage and production data management

A reliable control system improves operational efficiency while reducing human error.

Supporting Structure & Environmental Considerations

In addition to main functional units, supporting structures and auxiliary systems ensure long-term stability and compliance with site requirements.

These may include:

- Steel supporting frames

- Dust suppression and sealing structures

- Maintenance platforms and safety components

Proper structural design enhances durability and operational safety, especially in long-term or high-load production environments.

Integrated System Advantage

When these components are properly matched and integrated, the aggregate batching plant becomes a high-efficiency material proportioning system that can be seamlessly connected to concrete batching plants.

This modular design allows manufacturers to offer:

- Standardized configurations

- Customized solutions

- Easy expansion or upgrading

How Does an Aggregate Batching Plant Work

An aggregate batching plant operates through a coordinated and automated process that ensures each type of aggregate is delivered in the correct proportion, at the right time, and with consistent accuracy. The entire workflow is designed to support continuous production for concrete plants.

Below is a typical working process of an aggregate batching system:

Step1 Aggregate Storage and Feeding

Different sizes of aggregates are stored separately in designed aggregate bins. Based on the production recipe, the system activates the corresponding feeders to discharge materials from each bin.

Stable and controlled feeding at this stage is essential to avoid material blockage, segregation, or sudden flow variations.

Step2 Automatic Weighing and Proportioning

As aggregates are discharged, they are measured by the aggregate weighing system according to preset ratios. Sensors and load cells continuously monitor weight data to ensure batching accuracy.

Once the target weight is reached, feeding stops automatically, ensuring each batch meets the required specification.

This step direclty determines:

- Aggregate proportion accuracy

- Material utilization efficiency

- Consistency of the final concrete mixture

Stpe3 Aggregate Conveying to Mixing Unit

After weighing, aggregates are transferred to the mixing unit through belt conveyors or skip hoppers. The conveying system is synchronized with the mixer operation to maintain a steady production rhythm.

A well-designed conveying process helps:

- Maintain continuous material flow

- Reduce waiting time between batches

- Improve overall plant productivity

Step4 Centralized Control and Monitoring

All stages of the batching process are managed by a centralized control system. Operators can monitor real-time production data, adjust mix ratios, and store multiple production recipes.

Advanced control systems also enable:

- Automatic fault alerts

- Production data recording

- Easy integration with full batching plant control platforms

System Integration with Concrete Batching Plant

In practical applications, the aggregate batching plant works as a core material preparation system, seamlessly integrated with concrete batching plants.

Through synchronized control and matched capacity design, the entire plant operates as a unified system rather than isolated equipment.

Types of Aggregate Batching Plants

Aggregate batching plants can be configured in different forms depending on project scale, site conditions, mobility requirements, and integration needs. Understanding the main types helps contractors and plant owners select a system that best matches their production goals.

From a manufacturer’s perspective, these systems are typically designed to be modular, scalable, and compatile with complete batching plant solutions.

Stationary Aggregate Batching Plant

A stationary aggregate batching plant is designed for long-term, high-capacity production at fixed sites. It is commonly used in ready-mix concrete plants, large infrastructure projects, and industrial production facilities.

Key Characteristics:

- High production capacity

- Stable strucural design

- Suitable for continuous, lont-term operation

- Easy integration with stationary concrete plants

This type of system offers excellent batching accuracy and operational stability, making it ideal for projects where output consistency is critical.

Mobile Aggregate Batching Plant

A mobile aggregate batching plant is designed for projects that require frequenct relocation or have limited site preparation conditions, such as road construction, remote infrastructure projects, or temporary batching stations.

Key characteristics

- Compact and modular structure

- Fast installation and dismantling

- Easy transportation between sites

- Suitable for short- to medium-term projects

Despite its compact design, a mobile system can still deliver reliable batching accuracy when properly configured.

Aggregate Batching System for Concrete Batching Plants

In most concrete production facilities, the aggregate batching plant functions as an integrated subsystem within a complete concrete batching plant.

These systems are designed to match:

- Mixer capacity

- Cement and water dosing systems

- Overall plant production rhythm

A properly matched aggregate batching system ensures smooth coordination between material preparation and mixing, maximizing overall plant efficiency.

Customized & Modular Aggregate Batching Solutions

For projects with special requirements – such as limited space, unusual aggregate sizes, or future expansion plans – customized aggregate batching solutions offer greater flexibility.

Modular design allows:

- Flexible bin number and capacity selection

- Easy system expansion or upgrading

- Adaptation to different site layouts

Key Factors When Choosing an Aggregate Batching Plant

Selection the right aggregate batching plant is not only about equipment price or capacity. A well-matched system directly affects production efficiency, material consumption, operational stability, and long-term operating costs.

Below are the key factors that should be carefully evaluated before making a decision.

Required Production Capacity

The first consideration is the required production capacity, usually expressed in cubic meter per hour (m³/h) or matched to the output of the concrete mixing plant.

An undersized aggregate batching system may cause production bottlenecks, while an oversized system increases initial investment and operating costs.

A professional manufacturer typically offers multiple capacity options and can match the aggregate batching plant precisely to the overall plant design.

Number of Aggregate Bins

The number of aggregate bins determines how many different aggregate sized or types can be stored and batched simultaneously. Common configurations include:

- 2-3 bins for simple mix designs

- 4-5 bins for standard concrete or asphalt production

- Multi-bin systems for complex gradation requirements

Choosing the right bin configuration improves batching flexibility and reduces manual intervention.

| Models of Batching Machine | Number of Storage Bins | Hopper Capacity | Capacity of Storage Bucket | Productivity | Accuracy | Number OF Aggregate Types |

| PLD800 | 2 or 3 | 0.8m³ | 2×3.2m³ 3×3.2m³ | 48m³/h | ±2% | 2 or 3 |

| PLD1200 | 2 or 3 or 4 | 1.2m³ | 2×7.3m³ 3×7.3m³ 4×6.6m³ | 60m³/h | ±2% | 2 or 3 or 4 |

| PLD1600 | 2 or 3 or 4 | 1.6m³ | 2×6.38m³ 3×8.38m³ 4×10.0m³ | 80m³/h | ±2% | 2 or 3 or 4 |

| PLD2400 | 2 or 3 or 4 | 2.4m³ | 2×10.0m³ 3×8.38m³ 4×10.8m³ | 120m³/h | ±2% | 2 or 3 or 4 |

| PLD3200 | 4 | 3.2m³ | 4×15.6m³ | 160m³/h | ±2% | 4 |

| PLD4800 | 4 | 25m³ | 4×25m³ | 280m³/h | ±2% | 4 |

Aggregate Size and Moisture Conditions

Aggregate size variation and moisture content directly influence weighing accuracy and material flow beharvior. A well-designed aggregate batching plant should:

- Handle different aggregate sizes smoothly

- Maintain stable feeding under varying moisture conditions

- Minimize materials sticking or blockage

Manufacturers with full product chains can optimize feeder design and weighing sytems based on real project conditions.

Weighing Accuracy Requirements

Batching accuracy is a critical factor, especially for projects with strict quality standards. High-quality aggregate batching plants are equipped with:

- Precision load cells

- Stable weighing structures

- Intelligent control algorithms

Higher accuracy leads to:

- Consistent concrete or asphalt quality

- Reduced raw material waste

- Improved production control

Site Conditions and Mobility Needs

Site layout, foundation conditions, and project duration all affect whether a statioanry or mobile aggregate batching plant is more suitable.

Key considerations include:

- Available installation space

- Transportation and relocation frequency

- Site preparation requirements

Modular and mobile solutions offer flexibility for projects with changing site conditions.

Automation Level and Maintenance

Automation level influences labor cost, operational efficiency, and ease of management.

Modern aggregate batching plants typically feature:

- PLC-based automatic control

- Recipe management and data storage

- Fault diagnosis and alarm systems

At the same time, ease of maintenance – such as accessbile structures and standardized components – helps reduce downtime.

System Compatibility and Future Expansion

An often-overlooked factor is whether the aggregate batching plant can be easily integrated with existing equipment or expanded in the future.

A modular system design allows:

- Seamless integration with concrete batching plants

- Capacity upgrades as proudction demand grows

- Component replacement without major reconstruction

Typical Applications of Aggregate Batching Plants

Aggregate batching plants are widely used across various construction and industrial projects where consistent material proportioning and stable production are required. By adapting configurations and capacities, these systems can support both samll-scale operations and large infrastructure developments.

Ready-Mix Concrete Plants

In ready-mix concrete production, the aggregate batching plant serves as the foundation of the entire batching process. Accurate aggregate proportioning ensures uniform concrete quality across different mix designs and production cycles.

Typical benefits include:

- Stable concrete strength and workability

- Reduced material waste

- Smooth coordination with mixers and cement dosing systems

Road and Highway Constructure Projects

For road, bridge, and highway construction, aggregate batching plants are often used in conjunction with asphalt mixing plants or mobile concrete batching plants.

These projects require:

- Continuous aggregate supply

- Reliable batching accuracy

- Adaptability to changing site conditions

Mobile or modular aggregate batching systems are particularly suitable for such applications.

Infrastructure and Industrial Projects

Large-scale infrastructure projects – such as airports, ports, industrical parks, and power plants – place high demands on production stability and system durability.

Aggregate batching plants used in these proejects are typically designed for:

- High-capacity operation

- Long-term continuous production

- Integration with centralized plant control systems

Asphalt Mixing Plant Applications

In asphalt production, aggregate batching accuracy directly affects asphalt gradaition and pavement performance.

Aggregate batching systems for asphalt plants are optimized to:

- Match asphalt plant capacity

- Maintain stable feeding at high temperatures

- Support precise gradation control

Customized Project Applications

Some projects require customized aggregate batching solutions due to unique site conditions, special aggregate types, or future expansion plans.

Through modular design and flexible configuration, aggregate batching plants can be tailored to meet specific project requirements while maintaining reliable performance.

Why a Reliable Aggregate Batching System Matters

In practical production, the performance of an aggregate batching plant directly determines the overall efficiency and stability of a concrete or asphalt plant. A reliable system is not just about accurate weighing – it influences cost control, production rhythm, and long-term operational performance.

Consistent Material Proportion and Quality

Accurate and stable aggregate batching ensures that each production cycle follows the designed mix ratio. This consistency is essential for maintaining uniform concrete strength, asphalt gradation, and overall material quality.

Improved Production Efficiency

A well-matched aggregate batching system synchronizes smoothly with the mixer and downsteam equipment. Stable feeding and precise weighing reduce waiting time between batches and help maintain continuous production.

Reduced Material Wasted and Operating Costs

Inaccurate batching leads to excess material consumption and frequent mix adjustments. A reliable aggregate batching plant minimizes raw material waste, directly lowering production costs over time.

Better System Integration and Scalability

Modern aggregate batching plants are designed as part of a complete batching solution. Modular structures and standardized components allow easy integration, system upgrades, and future capacity expansion without major reconstruction.

FAQs of Aggregate Batching Plant

Is an aggregate batching plant the same as a concrete batching plant?

No. An aggregate batching plant is a subsystem responsible for storing, weighing, and proportioning aggregates. A concrete batching plant is a complete system that also includes cement, water, admixture systems, and the mixer.

How many aggregate bins are typically required?

The number of bins depends on mix design complexity. Common configurations range from 2 to 5 bins, while customized systems may include more bins for complex gradation requirements.

Can an aggregate batching be mobile?

Yes. Mobile aggregate batching plansts are widely used for road construction and temporary projects where frequent relocation or limited site preparation is required.

What batching accuracy can be achieved?

With high-quality weighing systems and automated control, aggregate batching accuracy can typically meet standard concrete and asphalt production requirements, ensuring consistent material proportioning.

Can one aggregate batching system be used for both concrete and asphalt plants?

In many cases, yes. With proper design and configuration, an aggregate batching system can be adapted to serve both concrete batching plants and asphalt mixing plants.

Conclusion

An aggregate batching plant is a critical system that ensures accurate aggregate porportioning, stable material supply, and efficient production for concrete and asphalt plants. From storage and weighing to conveying and automation, each component plays a vital role in overall plant performance.

Choosing a well-designed aggregate batching system helps improve product quality, reduce operating costs, and support long-term production stability. With modular configurations and full-range product options, manufacturers can provide tailored solutions to meet diverse project requirements.

If you are planning a new batching plant or upgrading an existing system, selecting the right aggregate batching solution si a key step toward reliable and efficient production.